For thin

wall crate plastic injection maker, The unit time output directly their

profit, and proportion of market share. Since it is most use for disposable use

crate, the strength and weight of thin

wall cplastic crate injection molding is the customer most consideration.

To thin wall crate manufacture, purchase

one economic and can bring more profit thin wall crate mould production line

becomes so important. Thus more and more crate maker be more seriously for the

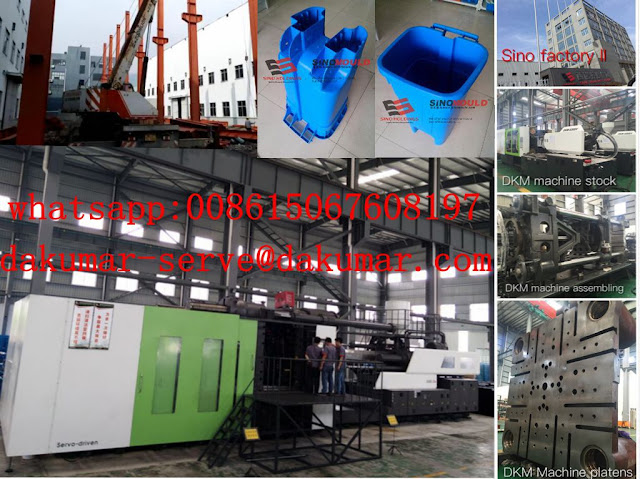

plastic crate mould maker choice and fast injection molding machine selection. Here comes best chance for you –Dakumar

Machinery company and Sino mould company. They are all branch company of Sino joint

stock Co.LTD. Develop itself support crate mould maker fast thin wall crate

injection molding line. From thin wall crate design, we will covers mold flow

to analysis best molding possibility, at same time, as much as possible to

reduce crate weight and raise the strength of the crate rib to satisfy its

weigh. Thanks so much to SINO mould professional technical team Constant

innovation and develop our thin wall crate design concept and the quality of

the production level. We could make high quality thin wall crate mould, the steel material we suggest

use H13 or other good steel material with Cu-Be for fast cooling.

About the thin wall crate injection molding

machine, Dakumar machine is the Solid Choice. Since the high speed injection

molding machine is specialize researched for the fast injection and thin wall

product. Which can realize mould open, material charging and ejection parallel

action. Greatly reduces the molding cycle time and further help customer save

the molding cost. We are offer turnkey molding solution, available for oversea

market engineer sending, and team work training. Just anything you have demand,

we can provide you support. welcome to make detail enquiry.

Post by Miss Tina

Email: serve@sinomould.com

Skype: anole-01

Whatsapp: 008615067608197