Sino holdings Group can offer you the fine solution for the turnkey molding line service. We have a very strong working team. Sino holdings group supply you the best plastic molding production line technology support from china. Molding line in Sino means, If the customer offer us the plastic product 3D drawing or plastic sample. We can offer him the best solution for his project, suggest him the mould cavity and the best injection machine for his mould. In Sino, we have a branch company mainly producing the injection auxiliary machine. So customer do not need to worry about whether their machine can suit their mould or not. Sino help you consider all the situation would happen and offer you the high quality one stop service.

|

| Injection Molding Line Service |

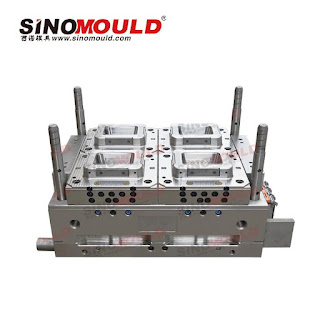

Mold service:Sino mould have more than 50-60 sales engineer. They are the professional mould making technology and accept specific training. Depend the customer special requirement, They will help the customer to make the mould comprehensive and specific scheme.

Sino mould treat design process as the important role for the mould project. Mould design is the beginning to start the project, it will affect the processing directly. In order to make the mould design more professional and correct, we made the mould design department separated into many branches. There are 6 branch designing department supply customer mould 3D design, mould 2D design, plastic product 3d design and design inspection. Before starting the project, We will inspect the drawing repeatedly and ask the customer confirm first.

Sino mould imported many precision machine for Mould making. Until now, Sino Mould total mold tooling equipment investment is around 20M USD. Sino annual making more than 1200 sets mould to meet the production requirement. In order to make these machine always working to produce the molds, the machining workshop working with 3 shifts. Each mould after finish machining would sent to the measuring department. Mould dimension would accept the high precision inspection. Measuring department mainly checking the mould dimension, mould accessory dimension, molded plastic sample dimension. Sino mould have many other department, like the QC department, the mould assembling department and the simulation department. These exist department plays important roles in the mould making and quality.

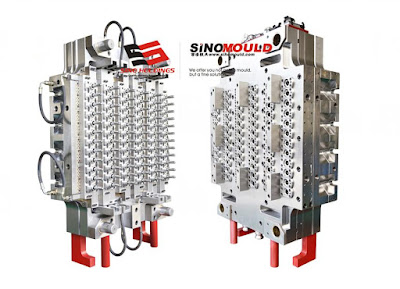

Hot runner service:

Anole hot runner is the brand of china. Offer customer mould analysis first before give them the hot runner system drawing. When the customer confirm the mold analysis, decide the preliminary design scheme as we suggested. Anole strong design team will make the 2D drawing and 3D final drawing for the customer confirm again. Then start to make the project production. Sometimes customer will ask Anole design the hot runner depend on their mould drawing, and also Anole accept design hot runner first then offer the customer detailed tooling drawings. Ensure that the mould makers will make the hot runner system housing according to the requested dimensions. Anole hot runner owns strong design and sales team. Also the hot runner system shows the top quality. Anole adopt German heating elements, the most durable and stable heating system in Germany. Top heating system plus top processing equipment and the strong working team, Anole comes out.

Before shipment, Anole hot runner will make the testing. We will confirm the product’s quality then send to the customer. Sino has its own testing mould department. If you also buy moulds in Sino, Anole will help to install the hot runner for the mould, then ensure the testing mould is ok. Then send the hot runner to customer with moulds. Can send engineers to make the hot runner repairing service to solve the customers’ worries for the future. Even if the hot runner system is not made by ANOLE, we also can offer the services for hot runner repairing.

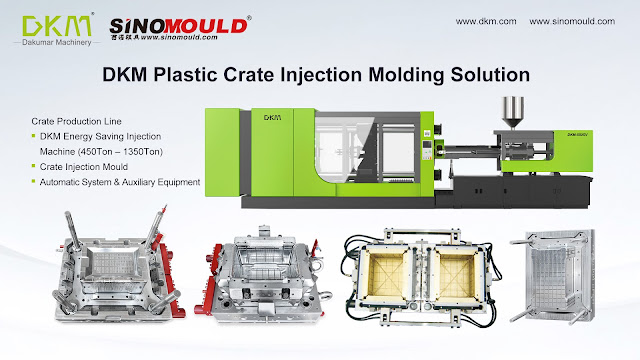

Injection machine service:

DKM is the one of the Chinese innovator for injection molding machine. There are variety kinds of injection molding machine model in DKM. DKM engineers all have more than ten years working experience in the molding machine industry. They will help customer to select the right mode machine to suit their mould.DKM also supply customer the molding machine auxiliary machinery to meet their plastic production. If the customer request, we can provide the plastic mold’s design and molding parameter suggestions. Also will offer the free training to the buyers’ workman.1 year guarantee time, DKM plastic molding machine offer all the damaged parts free of charge and response to parts assembling.

DKM keeps on increasing its investment and spend more 1 million dollars on high precision equipment from Germany, Japan, South Korea and Taiwan. We have more than 70 sets production equipment so far. Including FMS, Double Column machining Center, Vertical and Horizontal machining center and laser automatic cutting machine, and etc to ensure the high quality and high efficiency of products.

Sino mould, Anole hot runner and DKM machine owns their different agents in the world. If you need help and any requirement, please do not hesitate to contact Sino. We will be your best partner.