Thin wall crate is mostly using for the plastic fruit and vegetable for the normally transportation to the consume market or supermarket. And usually this is the once time usage. So for the plastic crate seller, weight and material price would be the No.1 consideration. Refer to the raw material cost, most vegetable crates producer prefer choose the recycle material and request the plastic crate mould supplier make the thin wall design to realize the light weight target.

Sino mould made high speed thin wall vegetable crate mould adopt high harden steel to make huge output and the advanced crate design with strength structure and light weight request. To make a thin wall vegetable crate, there has below technical difficulties:

1. Air venting problem

2. Mould cooling issue

3. Cycle time issue

4. machine need big size clamp force

5. Injection pressure issue

6. Flash and material forming issue

…

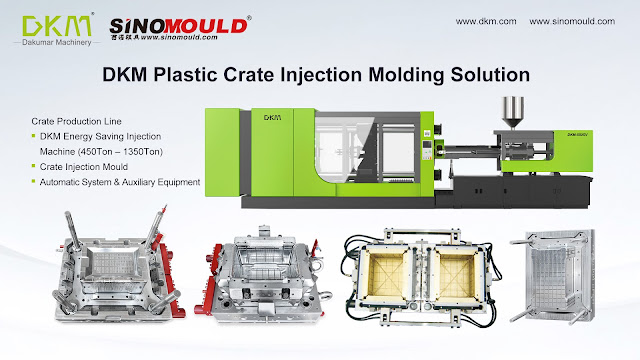

To help customer solve various molding difficulty, Sino mould cooperate with sister company -Dakumar injection molding machine company, arrange professional moldflow analysis, involve with structure mould structure adjustment, venting insert position, R angle design, clamp force suggestion and etc. To reduce the daily machine energy consumption, customer request to use small machine for production, as is know to all, thin wall fruit crate demand fast injection molding with high pressure shot.

DKM made high speed injection molding machine which specialize in the thin wall molding parts production for more than 20 years research and machine production. Our high speed injection molding machine can realize mould open, material charging and ejection at same time, mostly save the fruit mould production cycle time. And high pressure shot system with accumulator and Italy reducer, can faster the shot volume with unit time. DKM thin wall crate molding machine-high speed injection molding line manufacture and oversea market supply, welcome you make further consultation.

Whatsapp:008615067608197

Mail:dakumar-serve@dakumar.com