Sino mould is the professional plastic cap mould manufacture,especially for the unscrewing mould and the flip top cap mould,also common cap mould.this article will show you the detail for the thread cap mould production structure key point.

The key points for the plastic unscrewing cap mould:

1.Ensure the plastic cap appearance quality and adopt small injection gate nozzle or submarine gate

2.For the plastic parts,the inside tread forming structure design relate to the plastic quality and mould cost.

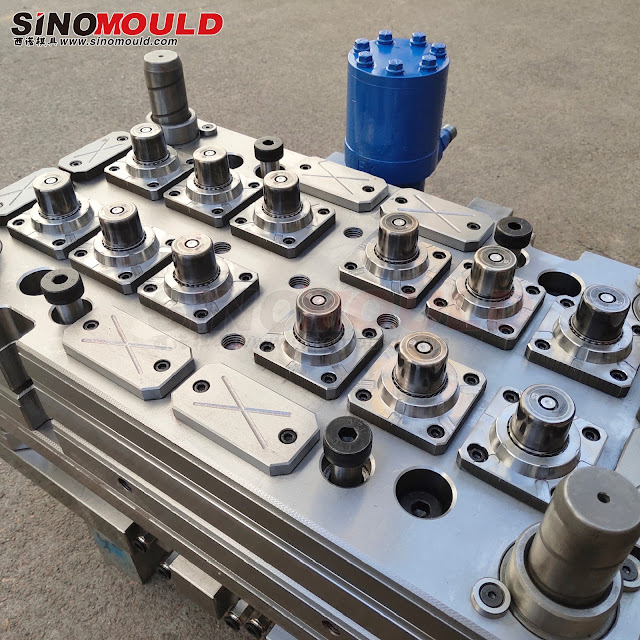

3.Considering the big quantity output,we should adopt multi-cavity mould production,and also need to consider the mould each part layout to ensure the mould strength and shrinkage the mould size.

There are three methods for this kinds of screw cap mould demould,one method is adopt screw motor to rotation the inside thread structure,But this structure complex,mould cost is high.Second method is use the extra hydraulic cylinder drive gear linear motion.That can make the plastic cap production stable,but that will lead mould size more bigger.The third method is using the inside slide,force to demould if the thread thickness not too big.But this method request very high processing request for the slide.

Plastic cap mould with high quality production standard and support long term stable running. Sino mould in rich manufacturing experience guide and improve mold quality, export of high quality plastic bottle cap mould is trustworthy.