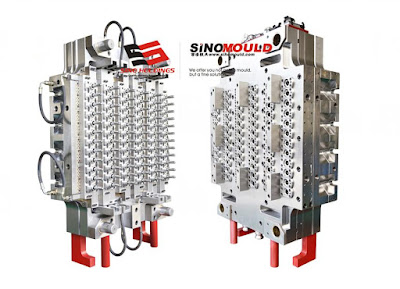

Sino Mould is an enterprise focusing on R&D and production of multi-cavity bottle preform injection mold. The PET preform mold provided has many advantages, such as fast speed, high blowing rate, durability, easy maintenance and so on.We are devoting to be the World famous plastic packaging industry system leader, make the injection molding more easily work.

Mould Marketing Field Advantage :

l 1-16, 24, 32, 48, 72, 96, 128 and 144 cavities with fully valve gate hot runner system

l Neck Size standard: ROPP, ALASKA, PCO1810, PCO1881, BPF, 30/25, 29/25, 26/22, 38mm, 48mm, 50-150mm etc.

l Valve gate injection systems such as YUDO,DME, HUSKY, NETSTAL and KATA...

l High precision temperature control system between each cavities

l High quality heating system for longest mould life

l Shortest cycle times,maximum output and highest process stability.

l Seeking common growth partners with our company's like-minded have long-term cooperation

For realizing multi cavity and high efficiency, Sino Mould has specially invested much money on developing 120 cavity PET preform mould with automatic running system. Through robot cooling system catch preform out could biggest increases production rate. Equipped with DKM PET preform special machinery,it realizes an efficient production line integrated with mould, injection machine and robot, and fulfills the special needs of many beverage packaging companies.

Further more, the global service & support team of SINO offer a complete range of preventative maintenance contracts, on-site breakdown cover, recommend spares, verification, re-calibration services and online remote support. Our sincerest thanks and application to all our customers for your constant support for loyalty over than past 21 years.